2026 Top Industrial Automation Trends You Need to Know

In today's fast-paced world, industrial automation trends are reshaping industries. Companies strive for efficiency and reliability. This drive leads to groundbreaking technologies and innovative solutions.

Automation not only streamlines processes but poses challenges. Businesses must navigate these complexities. Adopting AI and IoT can enhance operations. However, the cost and implementation hurdles can hinder progress.

As we explore the 2026 trends, it’s clear: understanding these shifts is essential. Companies that embrace change can thrive. Those that resist may find themselves falling behind. Adapting to industrial automation trends is crucial for future success.

Key Technologies Driving Industrial Automation in 2026

As we move towards 2026, several key technologies are shaping the future of industrial automation. One significant trend is the rise of Artificial Intelligence (AI) and Machine Learning (ML). According to a report by Deloitte, these technologies could boost productivity in manufacturing by up to 20% by 2026. AI enhances predictive maintenance, allowing companies to reduce downtime significantly. However, the initial integration can be costly and complex.

Another notable trend is the widespread adoption of the Internet of Things (IoT). A study by Industry Week estimates that smart connected devices will number over 75 billion globally by 2025. These devices can collect real-time data, improving decision-making processes. Yet, privacy and security concerns are rising. Companies must invest in robust cybersecurity measures, which can stretch budgets thin.

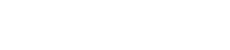

Moreover, the impact of advanced robotics cannot be overlooked. According to a report from McKinsey, collaborative robots, or cobots, are expected to grow by 35% annually. They work alongside humans, enhancing efficiency. However, integrating them into existing workflows can be challenging. Organizations often struggle to balance human and robotic tasks effectively. Reflecting on these challenges is essential for future success in industrial automation.

Impact of AI and Machine Learning on Automation Processes

Artificial Intelligence (AI) and Machine Learning (ML) are transforming industrial automation. They improve efficiency and accuracy in processes. For instance, predictive maintenance uses AI to forecast equipment failures. This extends machinery life and ensures production stays on track. However, adopting these technologies can be challenging.

Training staff is crucial, yet many companies overlook this step. Without proper training, workers may struggle with new systems. This can lead to resistance and decreased productivity. It's essential to create a culture that embraces change. Organizations should encourage continuous learning and skill development.

Integration of AI and ML requires investment and patience. Results may not be immediate. Some systems may fail initially, causing delays. Companies must learn from these setbacks. Tailoring solutions to specific needs is vital. A one-size-fits-all approach seldom works. Embracing imperfections can lead to innovations in automation processes.

Emerging Robotics Applications in Industrial Settings

Emerging robotics applications in industrial settings are revolutionizing the landscape. Recent reports indicate that the global industrial robotics market is expected to reach $75.9 billion by 2026. This growth is driven by advancements in automation technologies. Factories are increasingly adopting collaborative robots, or cobots, which work alongside human workers. These machines enhance efficiency and safety.

However, the integration of robotics poses challenges. In a survey, 30% of companies reported difficulties in training employees to work with robots. Companies must address these gaps to maximize productivity. Moreover, the maintenance of robotic systems can be costly. A recent study highlighted that unplanned downtime due to robotic failures could result in losses exceeding $5 million annually.

Another interesting trend is the rise of AI-powered robots. These robots can learn from their environment and improve over time. But, that brings questions about reliability. Statistics show that nearly 15% of firms experienced malfunctioning robots. This can lead to significant disruptions in production. As industries move forward, addressing these concerns remains crucial for successfully leveraging robotics in manufacturing.

IoT and Connectivity Trends Enhancing Automation Efficiency

The rise of IoT and connectivity is reshaping the landscape of industrial automation. As devices communicate seamlessly, efficiency is becoming a top priority. Factories are now more connected than ever, and real-time data flows enhance decision-making processes. Monitoring systems can pinpoint inefficiencies quickly. This creates an agile environment where quick adjustments are possible.

However, challenges remain. Cybersecurity is a major concern as more devices connect to the cloud. The vulnerability of data must not be underestimated. It requires continuous monitoring and updates. Companies must invest in proper safeguards, or they risk facing significant setbacks.

Tips: Start small by integrating IoT solutions gradually. Ensure all your devices can communicate effectively before expanding. Regularly review your data security measures to keep your systems safe. Automation can bring great benefits, but it also necessitates careful planning and ongoing evaluation. Emphasizing flexibility in your strategies is vital. Staying aware of the technological shifts will help companies remain competitive.

Sustainability Initiatives in Industrial Automation Practices

Sustainability is becoming a critical focus in industrial automation. Companies are seeking ways to reduce their environmental footprint. This shift is not only beneficial for the planet but can also lead to cost savings. Automation techniques are evolving to support these goals effectively.

One way to enhance sustainability is through energy-efficient systems. These systems monitor energy usage and optimize operations. They can significantly reduce waste and lower costs. Implementing smart technologies helps plants use energy more responsibly.

Tips: Consider regularly auditing your energy usage. Identify areas for improvement. Engage employees in sustainability training. This can lead to innovative ideas for eco-friendly practices. Small changes can yield big benefits.

Additionally, recycling becomes vital in automation practices. Many industries are exploring how to repurpose materials and reduce waste. A circular economy mindset encourages sustainable manufacturing processes. Yet, companies must reflect on their practices. Are they genuinely committed to sustainability, or is it just a trend?

Related Posts

-

Top 10 Automation Supplies Every Business Needs for Efficient Operations

-

Top 10 Motion Automation Best Practices for Enhanced Efficiency?

-

Top 10 Automation Solutions in Wisconsin for Businesses in 2023

-

What is the Role of Automation Laboratories in Modern Research?

-

Top 10 Benefits of Food Automation for Modern Restaurants

-

What is Automation Control Systems and How Do They Work?

© 2025 Tri-Phase | Privacy Policy | Purchase Terms & Conditions | Terms & Conditions