What is Automation Control Systems and How Do They Work?

Automation control systems are revolutionizing industries by enhancing efficiency and precision. According to Dr. Emily Lancaster, an expert in automation, "These systems are key to achieving seamless operations." Her insight captures the essence of how automation impacts various sectors.

In today's fast-paced world, automation control systems manage processes that are complex and demanding. They help in monitoring activities in real-time, reducing human error, and saving time. For instance, in manufacturing, these systems ensure machines operate smoothly with minimal downtime.

However, there are challenges. The integration of automation control systems can be tricky. Companies often face issues related to compatibility and training. The rapid evolution of technology requires constant adaptation. Thus, while these systems are powerful tools, they also demand thoughtful implementation and ongoing evaluation.

Definition of Automation Control Systems and Their Significance

Automation Control Systems (ACS) are essential in modern industries. They streamline processes, increase efficiency, and reduce human error. According to a report by Markets and Markets, the global automation control systems market is expected to reach $291.5 billion by 2025. These systems encompass hardware and software that monitor and control industrial processes. They play a critical role in sectors like manufacturing, energy, and transportation.

The significance of ACS lies in their ability to optimize operations. They provide real-time data, allowing for quick decision-making. Systems can be programmed to execute tasks with precision. However, the integration of these systems can present challenges. Inadequate training can lead to incorrect operations, negating potential efficiency gains. Organizations must evaluate their implementation strategy thoroughly.

Tips: Ensure comprehensive staff training on the new systems. Repeat training sessions can help reinforce learning. Regularly update the software to maintain optimal performance. Take time to assess areas that might require improvement in your automation approach. Even the most advanced systems can sometimes fail to address specific operational needs. Continuous feedback is necessary for growth.

Key Components of Automation Control Systems and Their Functions

Automation control systems play a crucial role in modern industries. They streamline processes, increase efficiency, and reduce human error. Understanding their key components is essential for effective operation.

Sensors are vital components. They collect real-time data from the environment. This data is sent to the controller. Controllers process the information. They make decisions based on predefined criteria. Actuators are another key element. They execute commands from the controller, controlling machines or flow of materials.

**Tip:** When implementing automation systems, regularly test sensors and actuators. Calibration is key for accuracy.

Another important element is the Human-Machine Interface (HMI). This allows operators to monitor and interact with the system. A user-friendly HMI can lead to better decision-making. Communication protocols are also significant. They ensure various components can work together effectively.

**Tip:** Keep communication protocols updated to avoid compatibility issues. This will save time and resources.

Continuously evaluating and refining these components is necessary. Over time, certain parts may become outdated. Regular maintenance keeps the system running smoothly. Such diligence prevents unforeseen breakdowns and enhances overall productivity.

Key Components of Automation Control Systems

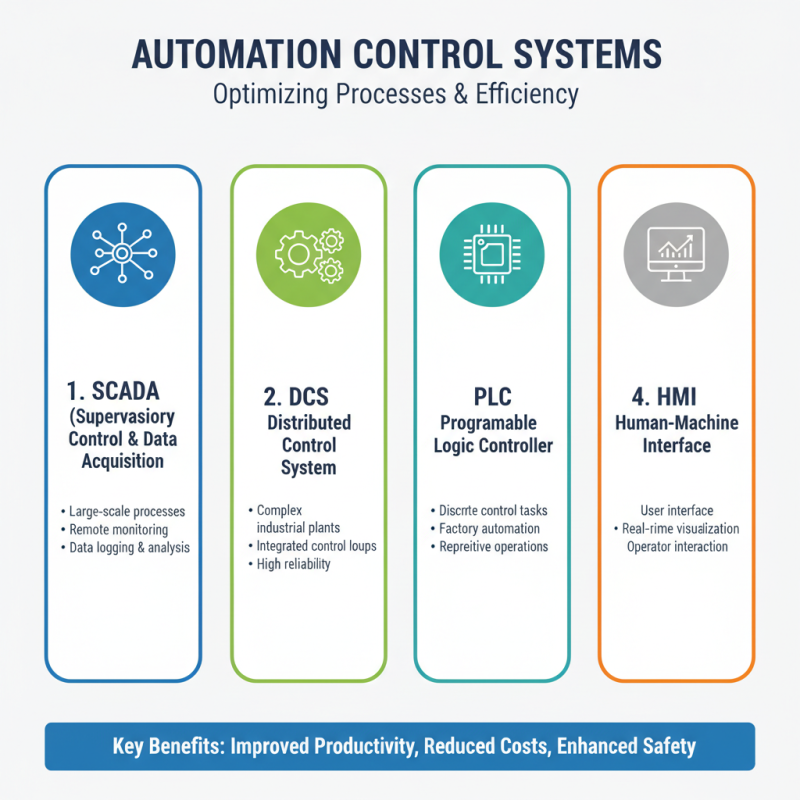

Types of Automation Control Systems: An Overview of Categories

Automation control systems play a crucial role in various industries. They can be categorized into several types, each designed for specific applications. Understanding these categories helps organizations optimize their processes and improve efficiency.

One common type is the Programmable Logic Controller (PLC). PLCs are widely used in manufacturing. They control machinery and equipment using programmable software. According to a recent industry report, the PLC market is expected to reach $10 billion by 2025. This growth indicates the rising reliance on automation in production environments. Another type is Distributed Control Systems (DCS). DCSs are often used in large-scale processes like oil refining and chemical production. Reports show that DCSs improve operational safety and system reliability.

Confusion sometimes arises over the choice of systems. Companies may overlook the nuances between PLCs and DCSs. Each system has unique strengths that fit specific needs. For instance, while PLCs excel in discrete control, DCSs usually handle continuous processes better. This distinction is vital to project success, yet many organizations struggle to select the right systems. Awareness and understanding of automation categories are essential for informed decision-making.

How Automation Control Systems Operate: Principles and Processes

Automation Control Systems are designed to manage and regulate machinery and processes. They play a crucial role in various industries, ensuring efficiency and reliability. At their core, these systems rely on a set of principles that govern how they operate. Sensors gather data from the environment, feeding it into a controller. This controller processes the information and issues commands to actuators, which perform actions.

Consider a factory setting. Machines must operate smoothly to avoid downtime. Automation Control Systems constantly monitor performance. They detect anomalies in real-time, responding quickly to issues. This is where human error often creeps in—data misinterpretation or delay can lead to costly mistakes. A well-implemented system can reduce risks significantly.

However, these systems aren't foolproof. Automation can fail due to software bugs or hardware malfunctions. Over-reliance on technology may blind operators to underlying problems. Continuous assessment and improvement of the systems are necessary. This iterative process often highlights gaps in understanding and opportunities for enhancement. It's a cycle of learning and adapting, crucial for success in automation.

Applications of Automation Control Systems in Various Industries

Automation control systems play a crucial role in various industries. For example, in manufacturing, these systems enhance productivity by optimizing processes. According to a report by McKinsey, productivity can increase by 20-30% through automation. This improvement is significant in competitive markets.

In the energy sector, automation controls help monitor and manage resources efficiently. The International Energy Agency (IEA) notes that advanced control systems can reduce operational costs by 10-15%. However, these systems can also pose challenges. Cybersecurity threats are a major concern, as increased connectivity can lead to vulnerabilities.

In agriculture, automation systems facilitate precision farming. Farmers utilize sensors and data analytics to improve crop yields. A study conducted by the Food and Agriculture Organization (FAO) indicates that automation can boost production by up to 25%. Yet, not all farmers have access to this technology. There remains a digital divide that needs addressing.

© 2025 Tri-Phase | Privacy Policy | Purchase Terms & Conditions | Terms & Conditions