Top 10 Automation Innovations in Germany Affecting Global Industry Trends?

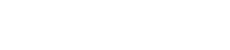

Germany is at the forefront of automation innovations that shape global industry trends. The country's focus on "automation Germany" has led to remarkable advancements across various sectors. According to a recent report by the International Federation of Robotics, Germany ranks third worldwide in industrial robot installations, showing a steady annual growth rate of 7% from 2020 to 2022. This growth is evident in manufacturing, logistics, and even healthcare.

Experts like Dr. Anna Schneider emphasize the significance of these innovations. She states, "The push for automation in Germany is not just about efficiency; it transforms how industries function globally." However, despite these advancements, challenges remain. Many companies struggle to adapt to rapid technological changes. Workforce training and integration of new systems pose barriers that require reflection and strategic planning.

Automation also raises concerns about job displacement. As industries increasingly adopt automation, the human element is at risk. Addressing these issues is crucial for sustainable progress. Ultimately, understanding both the benefits and challenges of automation innovations in Germany will provide insights into their global impact.

The Rise of Robotics in German Manufacturing: Key Statistics and Trends

The rise of robotics in German manufacturing is transforming global industry trends. This shift is driven by the increasing integration of advanced technologies. Robots enhance efficiency, reduce costs, and improve product quality. The adoption rate in Germany has soared over the last decade. Approximately 70% of manufacturers now utilize some form of automation.

Statistical data reveals striking trends. Germany ranks among the top three countries for industrial robot use. In 2021 alone, over 44,000 new robots were installed in manufacturing settings. This increase reflects a broader movement toward automation. Many companies are considering how to adapt to this rapid advancement.

**Tip:** Embrace change gradually. Start with small automation projects to test the waters. This approach minimizes risk and allows for adjustments as needed.

While robotics offers significant benefits, challenges remain. Skills gaps in the workforce can hinder effective implementation. Organizations must invest in training and education to bridge these gaps. Engaging employees in this transition is crucial.

**Tip:** Foster a culture of learning. Encourage your team to stay informed about automation trends. Open discussions can lead to innovative ideas and solutions.

Impact of AI on Production Efficiency: Insights from German Industries

In recent years, German industries have witnessed significant shifts in production efficiency due to artificial intelligence (AI). A report from the German Federal Ministry for Economic Affairs indicates that AI could enhance productivity by up to 30% over the next decade. This is an impressive statistic, yet implementing AI in manufacturing is not without its challenges.

Many companies face hurdles related to workforce adaptation. Employees may feel threatened by automation, which can lead to resistance. The installation of AI systems requires not only financial investment but also a culture shift. For instance, a survey from the Institute for Industrial Management revealed that nearly 45% of employees fear redundancy as AI takes over routine tasks. Balancing technology and human input is essential, yet often overlooked.

Furthermore, data accuracy is a critical issue. AI systems rely on quality data to make informed decisions. Errors in data can lead to misguided production strategies. One report noted that up to 20% of AI-driven changes were ineffective due to poor data quality. These points illustrate that while AI presents opportunities for greater efficiency, careful consideration and constant evaluation are necessary to maximize its benefits.

Top 10 Automation Innovations in Germany Affecting Global Industry Trends

| Innovation | Impact on Production Efficiency (%) | Industry Sector | Year Implemented | Technology Used |

|---|---|---|---|---|

| Robotic Process Automation (RPA) | 30% | Manufacturing | 2020 | AI, Machine Learning |

| Predictive Maintenance | 25% | Automotive | 2019 | IoT, Data Analytics |

| Cobots (Collaborative Robots) | 20% | Electronics | 2021 | AI, Robotics |

| 3D Printing | 15% | Aerospace | 2018 | Additive Manufacturing |

| Artificial Intelligence in Supply Chain | 35% | Logistics | 2020 | AI, Data Mining |

| Digital Twins | 28% | Energy | 2019 | IoT, Simulation Software |

| Automated Guided Vehicles (AGVs) | 22% | Warehousing | 2021 | AI, Robotics |

| Blockchain in Manufacturing | 18% | Pharmaceuticals | 2022 | Blockchain |

| Edge Computing | 30% | Telecommunications | 2021 | Edge Analytics |

| Augmented Reality (AR) in Training | 24% | Healthcare | 2022 | AR, VR |

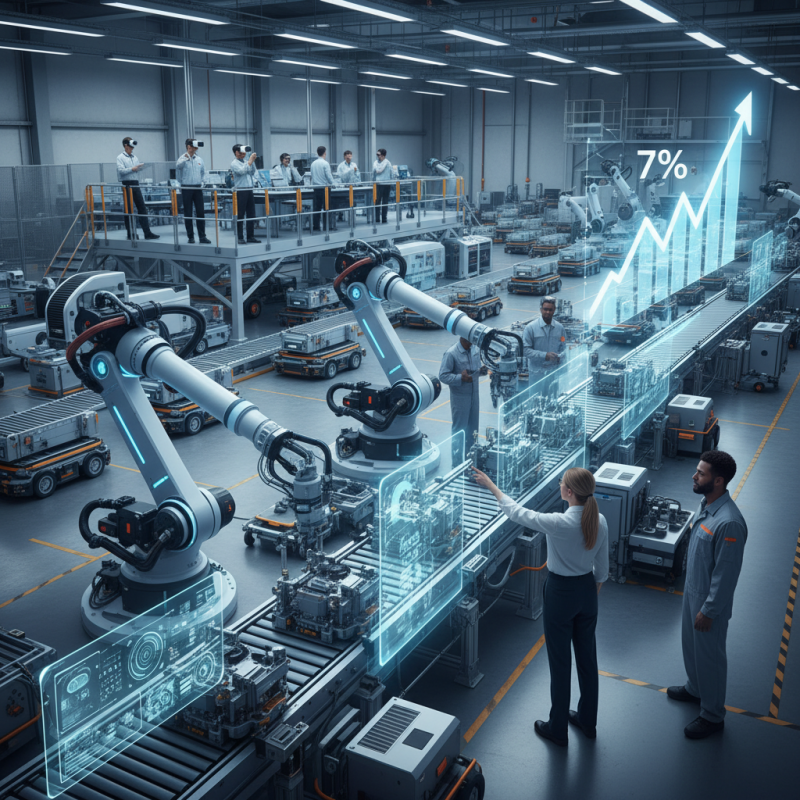

Germany's Role in the Global IoT Revolution: Data-Driven Innovations

Germany is a key player in the global IoT revolution. Its strong engineering roots fuel innovation across various sectors. Cities are increasingly adopting smart technologies to enhance urban living. For instance, sensors monitor traffic flow, optimizing movement and reducing congestion. This data-driven approach can transform industries, but challenges remain.

The manufacturing sector in Germany is witnessing a vast digital overhaul. Factories are integrating IoT devices, enabling real-time data collection. Machines communicate seamlessly, improving efficiency and lowering costs. However, this reliance on data raises concerns about privacy and security. The balance between innovation and safeguarding information is often difficult to strike.

Moreover, Germany's push for sustainability is influencing global trends. Smart grid technologies are being developed to optimize energy consumption. Ensuring that green initiatives align with technological advancements is crucial. The path toward a smarter, more sustainable future is promising but not without hurdles. Continuous reflection on these challenges will shape Germany's role in the global arena.

Sustainable Automation Practices in Germany: A New Industry Standard

Germany is leading the way in sustainable automation practices. This shift is redefining industry standards globally. Companies are now prioritizing eco-friendly methods. Automation technologies are becoming more efficient and less wasteful. This addresses environmental concerns and boosts productivity simultaneously.

Many factories are adopting smart sensors. These devices monitor energy consumption in real time. By doing so, they prevent energy waste and reduce costs. Utilizing renewable energy sources is another trend. Solar and wind power are increasingly powering automated systems.

Tips: Think about integrating energy audits in your operations. This simple step can identify inefficiencies. Consider the use of AI for process optimization. It can highlight areas needing improvement. Not every solution is perfect, so continuous evaluation is key. Embracing sustainable practices is not just about compliance. It’s about creating a better future for everyone.

Case Studies of German Automation Startups Shaping Global Markets

Germany is a hub for innovation, especially in automation. Numerous startups are changing global markets with their cutting-edge solutions. These companies focus on improving efficiency and productivity across various industries.

One noteworthy startup developed a system that automates indoor farming. This technology reduces resource consumption and increases yield. Another company focuses on supply chain automation. Their solutions enhance tracking and transparency in logistics. Both cases illustrate the effectiveness of automation in addressing complex challenges.

Tip: Embrace automation gradually. Start with small projects that demonstrate clear benefits. This approach reduces resistance and improves acceptance among employees.

Considering the rapid pace of change, startups often face challenges. Limited funding can hinder growth. Additionally, navigating international regulations may prove difficult. Yet, these obstacles can spark creativity, leading to unique solutions.

Tip: Foster a culture of adaptability. Encourage teams to share ideas and learn from failures. This mindset drives innovation and resilience.

Related Posts

-

What is Automation Control Systems and How Do They Work?

-

Top Tips for Electric Automation in Your Business?

-

Top 10 Motion Automation Best Practices for Enhanced Efficiency?

-

Top 10 Benefits of Food Automation for Modern Restaurants

-

2026 Top Industrial Automation Trends You Need to Know

-

What is the Role of Automation Laboratories in Modern Research?

© 2025 Tri-Phase | Privacy Policy | Purchase Terms & Conditions | Terms & Conditions