Top Tips for Electric Automation in Your Business?

Electric automation is revolutionizing the way businesses operate today. Experts in the field, like Dr. Emily Foster, have emphasized its importance. She once said, "The future of productivity lies in electric automation." This reflects the significant role this technology plays in enhancing efficiency.

In many sectors, electric automation drives cost reduction and boosts performance. Companies that resist this change may fall behind. Yet, implementing electric automation is not without its challenges. Staff may feel uncertain about their roles. Training is crucial, but it can be overlooked in haste.

Moreover, transitioning to electric automation requires careful planning. Businesses must consider both their immediate needs and future growth. Some may rush into automation without a clear strategy. This can lead to setbacks and wasted resources. Embracing electric automation means fostering an adaptable culture. It’s essential to reflect on the journey, acknowledging both successes and areas needing improvement.

Understanding Electric Automation and Its Benefits for Businesses

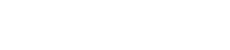

Electric automation is revolutionizing how businesses operate. By integrating automated electric systems, companies can enhance efficiency and reduce costs. According to a report by McKinsey, automation can boost productivity by up to 30%. This remarkable potential is driving companies to rethink their operational strategies.

The benefits of electric automation extend beyond mere productivity. It improves accuracy and reduces human error, leading to consistent quality. Enhanced data collection allows for better decision-making and innovation. Such insights can lead businesses to identify issues before they escalate. However, the transition to automated systems can be challenging. Employees may resist new technologies.

Here are a few tips to ease the process:

- Invest in training programs to help staff adapt to new technologies.

- Start with a pilot project to test systems before full-scale implementation.

- Gather employee feedback throughout the process to address concerns.

Navigating these challenges requires a thoughtful approach. Companies should expect some setbacks as they integrate automation. In doing so, they can steadily harness the full potential of electric automation for growth.

Identifying Key Areas for Electric Automation Implementation

In today’s business landscape, electric automation is becoming essential. To implement it successfully, identifying key areas is crucial. Research shows that companies can reduce operational costs by up to 30% through automation. This highlights the importance of strategically selecting where to implement changes.

One impactful area is production. Automating repetitive tasks can significantly increase efficiency. According to recent studies, businesses utilizing electric automation in production see a 25% boost in output. However, many companies overlook training employees to adapt to these systems. Without proper training, automation can lead to confusion and errors, negating potential benefits.

Another focus area is customer service. Implementing automated systems for handling inquiries can improve response times. A report from a leading industry body indicates that 70% of customers prefer automated responses for simple queries. Yet, a significant concern is the lack of a human touch in interactions. This often results in dissatisfaction. Balancing efficiency with empathy is key to successful automation. Implementing in these areas requires careful planning and constant evaluation.

Selecting the Right Technology and Tools for Electric Automation

When selecting the right technology and tools for electric automation, consider your specific industry needs. Research indicates that over 70% of businesses see a significant increase in efficiency when implementing automation. However, the selection process requires careful thought. Avoid rushing into decisions based solely on price or trends.

Tip: Analyze your current workflows. Identify repetitive tasks that could benefit from automation. This analysis can guide you to the right technology. For example, in manufacturing, implementing programmable logic controllers (PLCs) may enhance operation speed and accuracy. Yet, the complexity of these systems can be overwhelming.

Another key consideration is scalability. Your chosen technology should grow with you. Industry reports show that automation systems need to adapt as businesses evolve. Over 60% of companies express dissatisfaction with their initial choice of automation tools. Reflect on this data, and ensure your tools can expand or integrate with future innovations.

Tip: Engage with your team. Their insights and experiences can highlight what you truly need in automation tools. Balancing input can lead to smarter decisions and better outcomes.

Top Tips for Electric Automation in Your Business

Best Practices for Integrating Electric Automation into Existing Systems

Integrating electric automation into existing systems can transform business efficiency. A recent industry report revealed that companies adopting automation see a productivity increase of up to 30%. This integration isn’t just about technology; it’s about people. Creating a culture that embraces change is crucial.

Employee training is often overlooked. Research shows that 40% of employees feel unprepared for new technology. Businesses should prioritize skill development and provide hands-on training. This enables staff to adapt smoothly. Establishing a feedback loop is also essential. Regularly listen to employee concerns about automation. Their insights can reveal areas for improvement.

Moreover, collaboration between IT and operations teams can lead to better implementation. Silos hinder progress; shared goals drive success. In the automation journey, challenges will arise. However, with proper planning and a focus on communication, businesses can address these hurdles. Staying adaptable is key to long-term success in electric automation. Let’s not ignore the importance of continuous improvement in this dynamic landscape.

Measuring the Impact of Electric Automation on Business Performance

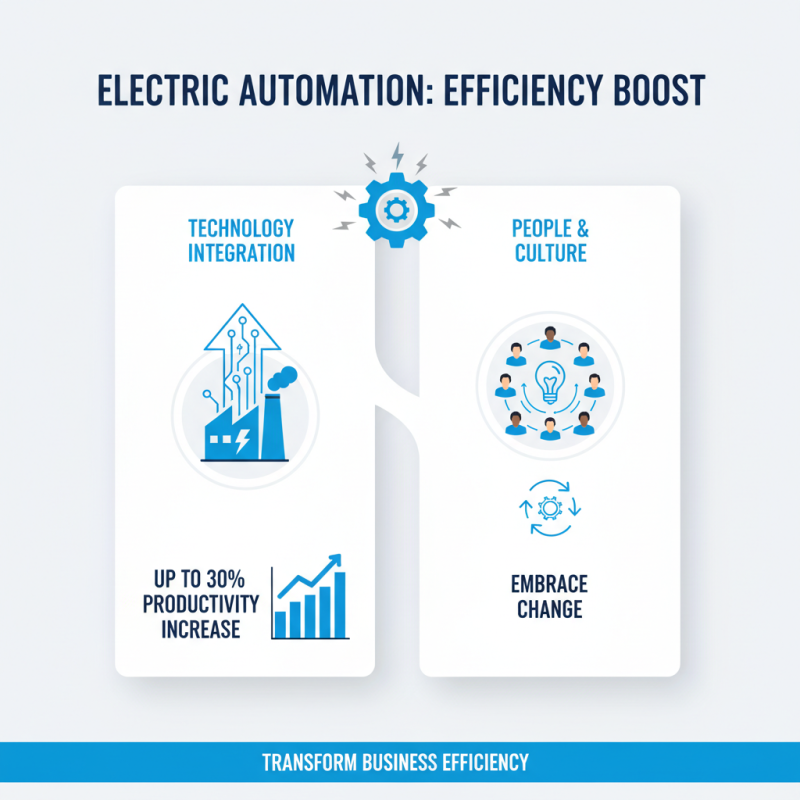

Electric automation can significantly influence business performance. Its impact is often measured in efficiency, accuracy, and cost reduction. When implemented thoughtfully, it can streamline operations. For instance, many businesses experience faster production cycles. However, the transition can come with challenges.

Tracking the results of automation is essential. Analyze data regularly to gauge performance. Are costs decreasing as expected? Are employees adapting well? Sometimes, automation can lead to a disconnect between teams. This is a point for consideration. A powerful tool can become a burden if not managed properly.

Changes in workflows must be monitored closely. Employee feedback can provide valuable insights. Some may feel threatened or resistant to new technology. Without proper implementation, those feelings might hinder productivity. Focus on creating a collaborative environment. Nurturing a culture of adaptation is crucial for long-term success.

© 2025 Tri-Phase | Privacy Policy | Purchase Terms & Conditions | Terms & Conditions