Optimized Automation for Wastewater Lift Stations

Reliable Solutions for Optimal Pump Performance and Municipal Efficiency

Tri-Phase Automation, a Diamond Elite Distributor of Mitsubishi Electric, provides cutting-edge wastewater lift station solutions trusted by municipalities and utilities. Designed for demanding environments, Mitsubishi Electric technology minimizes downtime, extends pump life, and boosts efficiency throughout the equipment lifecycle. With scalable automation, real-time diagnostics, and IoT-enabled monitoring, these lift stations are equipped to handle current challenges and future modernization needs.

How Smarter Solutions Benefit Wastewater Lift Stations

Prevent Lift Station Failures

Monitoring and Reporting Gaps in Lift Stations

Revitalize Aging Equipment

Reduced Energy Costs

Sanitary Sewer Overflows (SSOs) and unexpected pump failures cause costly downtime and environmental risks. Mitsubishi Electric wastewater lift station solutions minimize failures with anti-clogging features, certified startup support, and responsive service. These solutions prevent blockages, reduce manual interventions, and ensure continuous flow, extending equipment life and improving system reliability.

Reliable data is crucial for optimizing efficiency and maintaining compliance. With unified SCADA integration and Mitsubishi Electric solutions, wastewater lift station reporting is centralized. IoT-enabled sensors provide real-time pump diagnostics, alarms, and predictive maintenance alerts, giving operators actionable insights to enhance performance and reduce operational costs.

Aging pumps and sensors heighten the risk of unexpected failures. Mitsubishi Electric solutions simplify wastewater lift station upgrades, offering compatibility with retrofits, migrations, and existing networks. Facilities can modernize efficiently, enhancing reliability, extending component life, and ensuring compliance without significant disruption.

Lift stations are among the most energy-consuming components in wastewater systems. Mitsubishi Electric controls optimize pump acceleration, reduce standby power, and minimize downtime, lowering energy costs while supporting sustainability initiatives and meeting regulatory requirements.

How Smarter Solutions Benefit Wastewater Lift Stations

Preventative Maintenance

System Optimization

Modernization

Anti-clogging technology to reduce maintenance

Full support: programming, startup, and field engineering

Industry-leading warranty coverage

VFD protection with trip prevention

Control pump acceleration and reduce standby power to improve efficiency

Real-time monitoring and reporting for better system management

- Visualize system capacity and performance for optimized operation

Comprehensive VFD, PLC/HMI, and SCADA solutions for seamless integration

- Controls upgrades and expert startup services for optimized performance

- Enhanced component life

Your Guide to Smarter Lift Station Operations

Lift Station Pump Issues and Effective Solutions

Download the infographic to learn about common wastewater lift station challenges and explore proven solutions, including clog prevention, real-time monitoring, and modernization strategies that enhance performance and reliability.

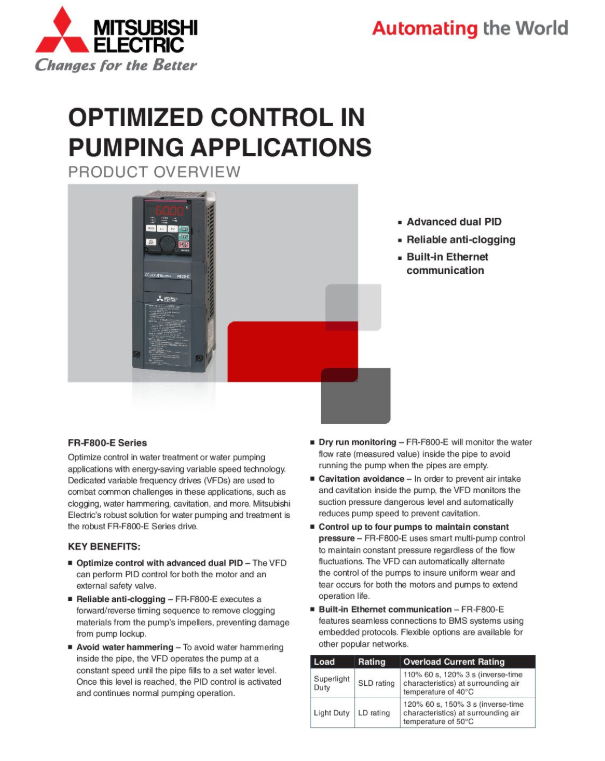

Optimized Pump Control for Water Treatment Applications

Enhance efficiency in water treatment and pumping systems with Mitsubishi Electric’s FR-F800-E Series variable frequency drives (VFDs). Equipped with advanced energy-saving technology, these drives help operators tackle common challenges like pump clogging, water hammer, and cavitation, ensuring reliable performance and long-term system protection.

Your Guide to Smarter Lift Station Operations

The primary causes of wastewater lift station failures include pump clogging, aging infrastructure, and inadequate monitoring. Mitsubishi Electric wastewater lift station solutions help mitigate these issues with built-in anti-clogging technology, predictive monitoring, and retrofit-ready designs that extend the life of pumps and ensure reliable operation.

Automation improves lift station performance by providing real-time pump monitoring, diagnostics, and reporting. This enables operators to identify issues sooner, optimize energy use, and minimize downtime. Centralized SCADA integration and IoT-enabled sensors enhance system visibility and streamline compliance reporting for more efficient operations.

Modernizing lift stations helps municipalities reduce energy costs, improve reliability, and extend the lifespan of pumps and control systems. Mitsubishi Electric solutions simplify the upgrade process with compatible VFDs, PLC/HMI, and SCADA systems, ensuring seamless integration with existing infrastructure for enhanced performance and efficiency.

Variable Frequency Drives (VFDs) optimize pump speed and reduce power consumption, particularly during standby periods. They also help prevent common issues such as water hammer and cavitation, enhancing energy efficiency while protecting equipment from premature wear and extending its lifespan.

Yes. As a Diamond Elite Distributor of Mitsubishi Electric, Tri-Phase Automation provides comprehensive support for both new wastewater lift station installations and modernization projects. From consultation and programming to startup services and ongoing support, Tri-Phase ensures reliable, high-performance operations throughout the entire lifecycle.